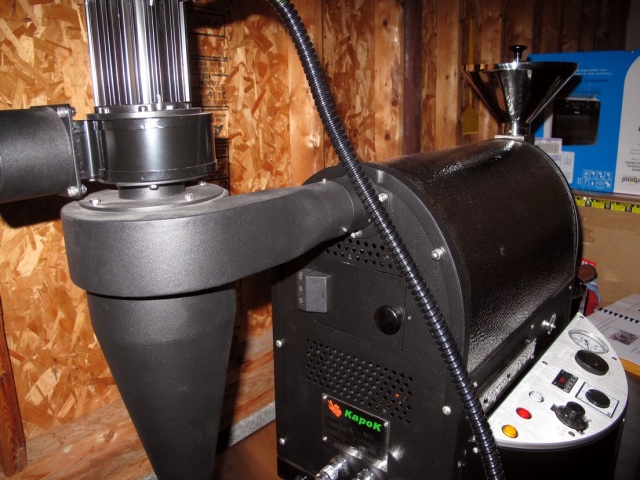

KapoK coffee roasters are produced in Kaoshung, Taiwan by KapoK Coffee Device Co.

I was supposed to visit the Kapok showroom in Kaohsiung but had to cancel in 2014. Subsequently a member of my coffee club bought the smallest model after much deliberation, considering the field of small professional coffee roasters. With permission from 9Sbeans, here are his thoughts and photos of a new KapoK 500 coffee roaster.

Thanks to 9Sbeans for sharing his KapoK 500 experience!

-

- December 27, 2014, 07:33:08 PM

KapoK?

Many coffee roasters are made in Taiwan (e.g. HotTop, Quest M3, Aillio, Huky, BellaTW/Yang-Chia, and KapoK) and they occupy diverse market segments. For the three 1-pound gas roasters; Huky 500 (~$1400) is an economical home roaster, whiles both BellaTW (Mini-500+~$3400) and KapoK (KapoK K500, ~$6000) are more oriented toward commercial setting.

KapoK continuously sponsors regional coffee roasting competitions, and gained most of its popularity after Yu-Chuan (Jacky) Lai won the World Coffee Roasting Championship in 2014.

Jacky owns three coffee roasting shops and uses KapoK 1-kg and 5-kg roasters. http://imsean.pixnet.net/blog/post/39407625- Since Jacky operated BellaTW roasters in the Taiwan regional competition and eventually got his title by using a Giesen W6, it should be fair to say that both BellaTW and KapoK are capable commercial roasters.

Hearsay

Some hearsay while I was researching KapoK. It is said that KapoK made and exported wood heating stoves/manufactured products to Germany, and thus had better safety features and build quality. I have never confirmed this with the owner, because it could be merely marketing strategies and I didn’t base my buying decision on it.

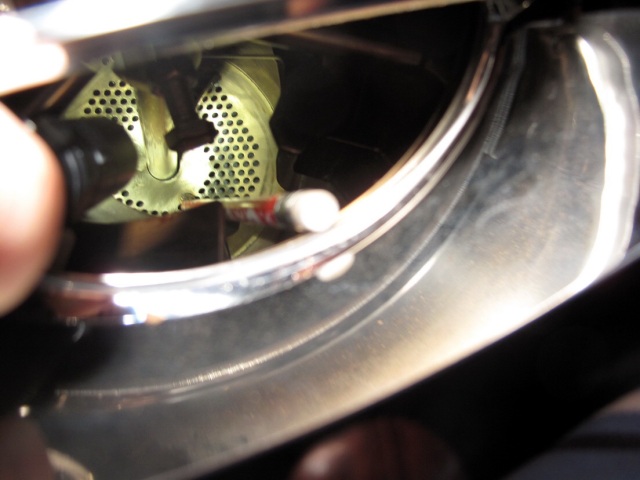

Some people claim that KapoK uses a computer-based aerodynamics simulation to design their fan/air flow; while most other roaster builders still go with the old-school, trial-and-error approach. It is interesting to know other roasters have solid/perforated drum options for distinct air flow control and roasting profiles. However, I’m no expert to know which roaster has superior internal air flow/minimized turbulence design.

Communications

I emailed several companies in Taiwan regarding detail specs/pricing discounts of their roasters. Among these companies KapoK was the slowest responding one. For example Mr. Jet Huang the sales manager of BellaTW, almost always responded my inquiries within couple of days.

On the other hand Mr. Frank Lin owner of KapoK, could have delayed answering my questions for up to two months; to a point that I almost forget the extent our “conversation”. On the bright side, Frank did address most of my question and even some of my harsh criticism. In my opinion the slow response was due to his pondering of answers, and wouldn’t reply if he didn’t have it correct. During the evaluation phase the communication was not good, but adequate.

After I decided to buy KapoK, there was about 50-days of build time without exchanging e-mails between us. I received notice when they performed the last testing phase of the roaster, got the UPS tracking number, and the communication has greatly improved since then.

Frank asked me to inspect the outside of the crate for potential shipping damage, and answered my installation questions immediately. He also gave me his personal Line (popular app in Taiwan) and Skype contacts even with the 12-hours time zone difference. I did not bother to call him though, because there were no installation issues. The user’s manual is concise with several typos; the illustrative pictures explained everything.

Pricing

Recently US dollars have gained strength in exchange for Asian currencies. It was around 1:30 (USD: New Taiwan Dollars) last year and now reaching 1:31.8. My price quote was in US dollar though. If you really want to buy a KapoK roaster, ask Frank nicely and try to negotiate some discounts. YMMV.

Delivery

I checked several shipping companies including UPS in Taiwan. Since I did not have the actual size of the package at the time, I only had estimated quotes from these companies. Basically KapoK chose UPS air freight delivering to my door, and prepared all necessary documents.

I got the tracking number, signed for the package, received statement from UPS for US customs duties (2.7%) & brokerage charges ($7), and made my payment to UPS by phone. I think the package had been inspected when imported. Shipping took about 10 days, and there was no damage.

Setup

The assembly of the machine was easy: electricity (wall socket to roaster, roaster to cyclone), gas (propane), and vent. The body of the roaster was heavy though, and required two people lifting it from the ground. I sent KapoK a standard US propane regulator assembly http://gashosesandregulators.com/lowpressureregulators.html for the fitting test, and got another new regulator assembly from our member Steve @ MillCityRoasters. Plug-in-and-Play. http://millcityroasters.com/

Color coded buttons – Green

The blue arrow is pointed at a green “main electric power” button. The green button will light on as long as there is power. Press this button to power up the system, including the drum motor and the white LED lamp.

Variable Drum Speed

This prototype K500 is equipped with a variable speed drum motor, with the white speed control panel above the green button. My hunch is that it can control drum speed between 50 to 140 rpm, and they are still testing the roasting profile correlations between drum speed and the final taste.

Variable Fan Speed

Most of the 1-pound sample roasters have an exhaust fan rotating at a fixed speed, and a mechanical shutter (or damper) installed to adjust the airflow rate. K500 is more advanced. It’s design of the linear variable speed fan controller ensures longevity for the motor and consistent/reproducible air flow.

I considered between the BellaTW Mini-500+ (with 12-steps mechanical damper) and K500 several months ago. For me, variable fan speed is a feature of “it would be nice to have ”,  but I’m no engineer to know if it’s overkill.

but I’m no engineer to know if it’s overkill.

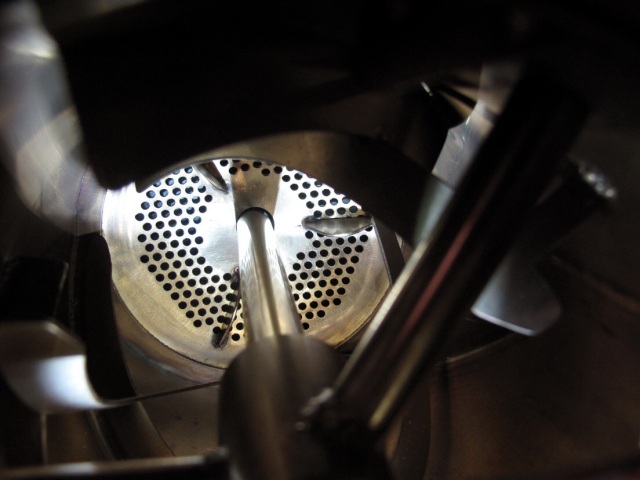

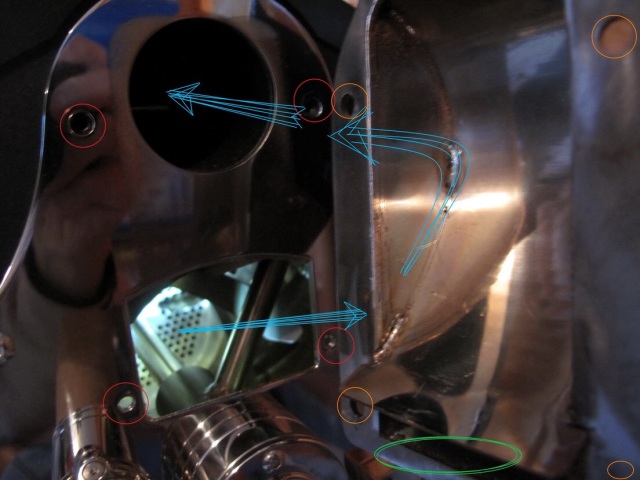

Air Flow

I removed the bean loading hopper as described in user’s manual. There are 4 screw bolts to loosen (the 4 red circles and 4 orange circles). Green beans can come out of the rectangular opening (green oval) and drop into the drum.

It’s my guess the hot air (blue arrows) flows cross the drum from the mesh to the hopper, and turns into the chimney. The ET probe might be the rod in the entrance of the chimney (between the blue arrow point and the upper-left red circle).

The distance between the flame to the drum wall is fairly close (direct heating), and the hot air flow resembles the indirectly heated drum roaster. I guess it’s the reason called “hybrid”.

Color coded buttons

Green

The green button will light on as long as there is power. Press this green button to power up the system, including the drum motor, vent fan, digital BT & ET displays, and the white LED lamp.

Yellow

After the system powers up, the gas sensor will detect pressure at the inlet. By opening the gas valve on a propane cylinder, the gas inlet pressure raises, and the yellow gas indicator lights (yellow).

Red

Press the red ignite switch button, burners fire up. Press it again to turn off the burners, red button light off.

White

Press the white button to turn the cooling tray fan on. Press it again to turn off.

Blue

This button is at the bottom of the control panel. Press it once to activate and yes, it’s Bluetooth ready. It can also be wired to a computer via the connector, as can be seen in a test run picture taken by the manufacture.

Vent speed

The air flow is manually controlled by the vent speed knob. Manufacture suggests 3.0 as a starting value and 5.5 for a fast system cool down after roast. Without the flame, I could dial the fan speed from 0 to 8.5. A user review said that the DC motor of the fan is regulated by an IC-controller for voltage regulation  , and he has measured the air flow rate being between 0.1 to 1.2 m^3/min.

, and he has measured the air flow rate being between 0.1 to 1.2 m^3/min.

I tried vent speed from 3.0 to 2.5 only once while burner is on, and observed an increased temperature rate rise. Conversely, vent speed 3.5 and 4.0 brings in cold air and slowdowns the temperature rising rate (note that the BT is still rising, just rises slower).

The vent provides slightly negative pressure inside the drum, and the negative pressure is monitored by the pressure sensor. An anecdote: A K500 user said that he once improperly installed the exhaust hose, and a gust of wind blew the air backward from the exhaust pipe to the roaster. The gas line was therefore shut off, leaving that user puzzled by the “igniting device malfunction”.

Theoretically, if I drop the vent speed low enough, I should be able to test the safety gas shut-off function as advertised. However, I don’t want to test this safety feature, since insufficient vent is usually associated with dangerous accumulation of carbon monoxide.  Unconfirmed feature for now.

Unconfirmed feature for now.

Automatic BT Mode

The temperatures dial lower right, now set to 50* C controls the switch between manual and auto BT mode. IMO, the auto mode is valuable in the warming up of the system and in the maintaining of charge temperature.

Manufacture recommends slow heat steps (for the lifetime of the drum) and 15-min. of equilibration time at charge temperature for the first roast of the day. Dialing this temperature control knob, I can set the target BT temp at 50* C, and gradually increase it to 180* C (the charge temperature) and would never worry about overheating of the drum.

In the auto mode, the gas pressure is switched between High, Low, and Off stages. For example, if the current BT is at 40* C and target BT is at 120* C, the gas will be in “High” until close to 117* C, and then switch to “Low” for slower approach, or “Off” for an overshoot (manufacture states 3.5% error of auto BT).

I actually roasted half-pound of green beans by the auto mode, and it tasted really good. I charged the beans, simply dialed the target BT at different time points, and voila I got Guatemala Antigua – Finca Pavon in Full City Roast.  But no thanks not again, I’ll do the full manual roast.

But no thanks not again, I’ll do the full manual roast.

To do the manual roast, just set the BT dial to a high enough temperature (250* C), and the system will be always in the “High” gas pressure mode. The user thus controls the gas pressure gauge and the vent speed, the same as all other manual gas roasters.

Bluetooth/wired Artisan support

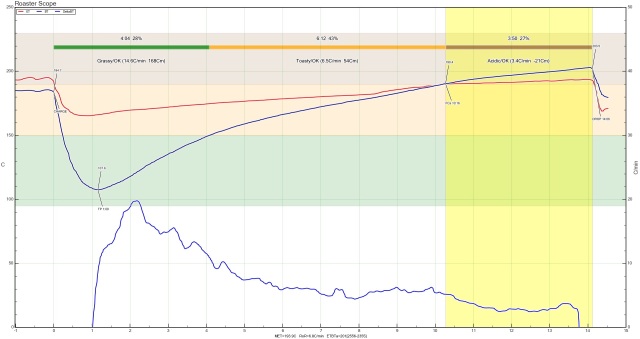

It was effortless to set up the Bluetooth connection. In the Artisan software, BT & ET were configured as “Delta DTA PID temperature controller”. I was not familiar with the software, and anyhow got my first roast with the data logging. As can be seen in the plot, before charge (-1 to 0 min), I set the BT targeting at 185*C to warm up the machine, and the BT was hovering around my target temperature.

After charge, the turn point was around 70 ~ 80 seconds (shown 1:09 on this plot). I increased the power (propane pressure) at around 8:30 (@ BT 179*C), and increased ventilation (from 3.0 to 3.5) at the 1st crack (BT 191*C). I was playing with vent speed (increasing 0.1 every 15 sec until 4.5), and it seemed that the increase of vent speed brought in cold air, and it decreased RoR while maintaining RoR at positive range.

The ET was lower than BT after 1st Crack; nevertheless, BT continued to increase and did not stall. I did not want to reach 2nd crack, therefore didn’t know exactly the BT readouts at this landmark. The stretching of development (3:50) might be too long, and I will know the results 4 days later

.

I will try to work out at least two different profiles, reproduce them consistently on the same types of beans, and then compare taste in the cup. KapoK and its users have accumulated hundreds of roasting profiles, and IMO this database is invaluable.

In summary, the machine and software were functional and well-integrated. The sky’s the limit, and the only questionable link is now the person operating the machine.

Sorry to comment on such an old post, but do you still have connections with KapoK or Bella TW?

I’m in the market for a 600 – 800g roaster and I ‘ve tried contacting both companies but not having much luck.

Thanks

LikeLike

Sorry you’re finding it difficult, it’s difficult as well for builders dealing with oversea customers. In November 2023 there’s a big Coffee trade show in Nangang, Taipei. You can buy a display coffee roaster at the trade show and get it shipped. lots of smaller roaster will be on display there.

LikeLike

Since traveling to Taiwan is not really an option, I guess I’ll wait and see if I get a response from the manufacturers that I contacted. I’m sure with all the global tensions everyone has a lot on their plate at the moment.

Thanks for the response.

LikeLike

If your in the US, Showroom Coffee has a lot of 800g Arc’s in the warehouse.

LikeLike

I’m in Arizona and am familiar with the Arc and the BC roasters. I’ve seen them both in person and wasn’t that impressed with the quality for the price.

I’m getting ready to retire and would like to buy something that will last as long as I do. I plan on roasting for friends and family with the possible foray into a few small local farmers markets.

I’m in Arizona and am familiar with the Arc and the BC roasters. I’ve seen them both in person and wasn’t that impressed with the quality for the price.

I’m getting ready to retire and would like to buy something that will last as long as I do. I plan on roasting for friends and family with the possible foray into a few small local farmers markets.

Not trying to make a business out of it but I love roasting and look forward to spending more time doing it.

LikeLike

Well, the Arc is a rebranded HB roaster from China, Buckeye sells one of the better bargain brands, then there’s Santoker out of China. In Taiwan the best selling locally made machine is Yang-Chia, Bella is the Far East dealer except China. Kapok is a level above Feima in price, quality, and finishing.

I do visit Bella in Taipei and Kapok in Kaohsiung occasionally. Nothing I can do till later on this year on Taiwanese machines. Neither Feima or Kapok make a 800g machine, Feima has a 500g or 1K and Kapok has a 500g and larger 1.5 that’s very popular in Taiwan.

The owner of Kapok bench tests every machine sold for 24 hours running hot; before delivery. The components of the machine are the best he can find; no corners cut on anything.

In the Kapok showroom are all three machines they produced hooked up for roasting. He was having a monthly get together for Kapok customers to hang out, roast, drink coffee, etc. Pretty cool thing to do.

Feima roasters are the “Toyota” and Kapok’s the “BMW” of Taiwanese machines.

LikeLike

How’s it looking to get a roaster out of Taiwan now?

LikeLike

No problem, I think!

LikeLike

Can I email you directly or would you rather me setup an account?

LikeLike